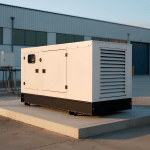

A diesel generator, whether an SDEC, FAW or Baudouin model is a highly engineered machine where mechanical, electrical, and electronic systems work in perfect unison. Understanding the main components of a diesel generator is vital for troubleshooting, identifying spare parts, and ensuring your backup power solution remains in peak condition.

A generating set, or “genset,” is far more than just an engine; it is a portable power plant. Here is an in-depth look at the primary components that make up a high-performance diesel generator.

1. The Engine: The Heart of the System

The engine is the primary power source of the generator. It converts the chemical energy in diesel fuel into mechanical (rotational) energy.

-

Combustion Cycle: Most industrial generators utilise a four-stroke compression-ignition cycle. Air is compressed to a high pressure, heating it up, before diesel is injected and spontaneously ignites.

-

Performance Metrics: Engine performance is measured by its displacement (litres), compression ratio, and rotational speed—typically 1,500 RPM in South Africa to produce the required 50Hz frequency for our electrical grid.

-

The Generator King Choice: We specialise in SDEC, FAW and Baudouin engines because they are engineered for durability and high torque, specifically designed to handle the frequent start-stops typical of South African loadshedding.

2. The Alternator: Converting Energy into Electricity

While the engine provides the “muscle,” the alternator provides the power. It converts the mechanical energy from the engine’s crankshaft into electrical energy through electromagnetic induction.

-

The Rotor and Stator: The rotor (rotating part) creates a moving magnetic field around the stator (stationary part), which induces an electrical current in the stator’s copper windings.

-

AVR (Automatic Voltage Regulator): This is a critical electronic component that regulates the output voltage. It ensures that whether your generator is running at 10% load or 90% load, the voltage remains stable (typically 230V or 400V), protecting your sensitive electronics from surges.

3. The Fuel System

For a generator to provide reliable backup power South Africa, its fuel delivery must be flawless.

-

Fuel Tank: Most sets feature a “day tank” built into the baseframe, usually sized to run the generator for 8 to 12 hours at 75% load.

-

Filtration: Diesel fuel can contain impurities or water. High-quality primary and secondary fuel filters are essential to protect the high-pressure fuel injection pumps used in SDEC, FAW and Baudouin engines.

-

The Lift Pump and Injectors: These components ensure the diesel is delivered at the exact pressure and timing required for efficient combustion.

4. The Control Panel: The Brain of the Unit

The control panel is the user interface and the “command centre” of the genset. Modern units utilise advanced digital controllers like the SmartGen series.

-

Monitoring: It displays real-time data, including voltage, frequency, current (Amps), oil pressure, and coolant temperature.

-

Protection Alarms: The controller acts as a safeguard. It will automatically shut down the engine if it detects a critical fault, such as low oil pressure or high engine temperature, preventing catastrophic engine failure.

-

Automation: In a standby setup, the control panel communicates directly with the Automatic Transfer Switch (ATS) to start the unit the moment the mains power fails.

5. Cooling and Exhaust Systems

Industrial engines generate immense heat and toxic by-products that must be managed safely.

-

The Cooling System: Most industrial generators are liquid-cooled. A water pump circulates coolant through the engine block, and a radiator and fan dissipate that heat into the atmosphere.

-

The Exhaust System: This directs toxic fumes away from the engine. It includes a silencer (muffler) to reduce the decibel levels of the engine. In residential areas, we utilise high-specification “silent” silencers within acoustic canopies to ensure minimal noise disruption.

6. The Lubrication System

To ensure longevity, the moving parts of the engine must be continuously lubricated.

-

Oil Pump and Filter: An internal pump circulates engine oil under pressure to the bearings, pistons, and camshaft. Regular oil and filter changes are the most important part of any maintenance schedule to ensure your unit reaches its full operational lifespan.

7. The Baseframe and Battery System

-

Baseframe: The entire unit is mounted on a heavy-duty steel baseframe. This frame often incorporates anti-vibration mounts to reduce the transfer of mechanical energy to the ground.

-

Battery and Charger: Like a car, a generator needs a battery to crank the engine. Standby generators include an on-board “trickle charger” that uses mains power to keep the battery at 100% readiness, ensuring the unit starts instantly when loadshedding hits.

Conclusion: Quality Components for Total Reliability

A generator is only as reliable as its weakest component. By choosing a Generator King unit, you are investing in a machine built with world-class SDEC, FAW or Baudouin engines, precision-engineered alternators, and advanced digital control systems.

Understanding your generator is the first step toward better maintenance. Contact Generator King today for genuine spares, expert servicing, or to discuss a new diesel generator for sale tailored to your power needs. Alternatively, Get A Quote now!

By the Generator King Technical Team